Why Dont Hardware Stores Sell 3 Phase Breaker

Warehouse automation became widely recognized over the last few years. Transmission operations get mitt in paw with human errors resulting in delays, improper time and resource management, low productivity and margin. All this ultimately leads to unsatisfied business partners and customers. And while some think of automation every bit applying democratic vehicles and robots, others choose to first with software. As always, the truth is somewhere in between.

Total warehouse automation covers many aspects and operations, from automatic data entry to goods storage and delivery. In this guide, we're explaining its primary layers - automation basics, hardware and software solutions, their advantages, and featuring some real-life cases to cheque.

What is Automatic Warehousing

Warehouse automation is all about uncovering repetitive tasks and finding ways to automate them. Modernistic warehouses are full of cases – from manual data entry to picking, storing and shipping of appurtenances done past mitt.

A large function of retail companies' success lies in their ability to create effective supply chains, cut costs and thus expenses. In turn, this can be achieved with the assist of an automated warehouse arrangement covering the almost of import warehouse operations. They often include inventory and back-office management, picking and commitment, barcodes scanning, handling charges, etc.

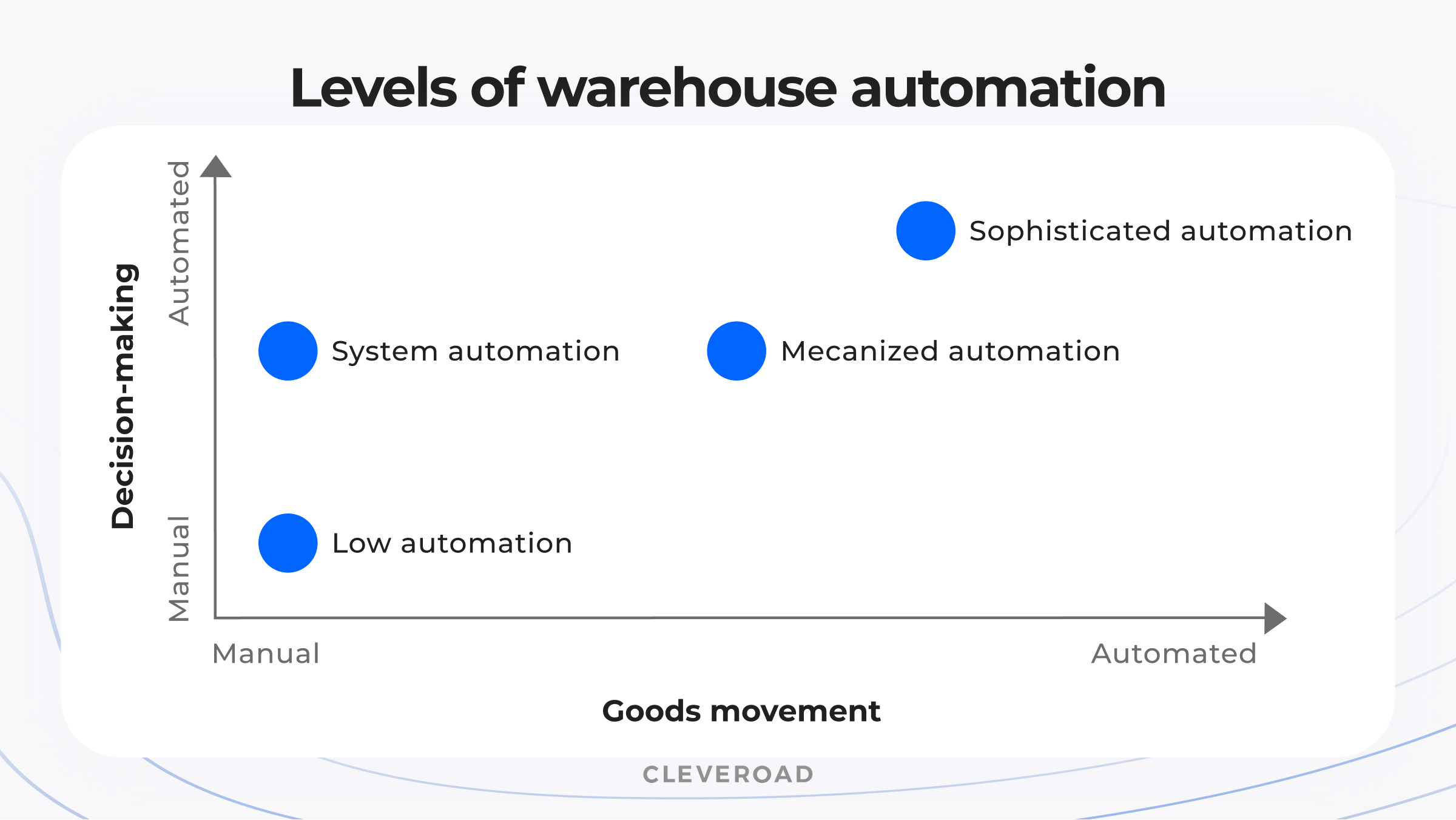

And so far, nosotros can define iv layers of warehouse automation:

- Basic automation (use of specific scanners, applications, printed papers)

- Sysеem automation (apply of WMS, mobile radio frequency, vocalism-directed technologies)

- Mechanized automation (conveyors, As/RS)

- Advanced automation (automatic sorters, palletizer, robotic picking, AGVs, and AGV software)

Iv layers of warehouse automation (Source: Westernacher Consulting)

As yous see, there are diverse automation solutions, some of which nosotros're going to review afterwards on. And so to cull the right i, y'all demand to be fully aware of the company's current baseline, future goals, and budget limits. Moreover, such solutions refer to Logistics. It's a time-consuming and specific area, requiring unique expertise. Then it's better to turn to a software development company experienced in this niche.

How Practise Automated Warehouses Work?

Allow'southward say, operators load a robot with large bundles. The robot takes the cargo from one bespeak of the warehouse to the dispatching zone and warehouse software tracks the cargo's motion, updating data regularly. However, not all warehouse solutions need robotic automation. In some cases, they are limited to utilizing software to supervene upon manual tasks.

Warehouse automation intends to guarantee that the enterprise-strategic operations of your company satisfy consumers' demands. All the repetitive tasks, information gathering, inventory command, and maintenance data analysis are automated by a warehouse management arrangement (WMS). These systems easily integrate with different solutions (e.k. inventory direction software) to computerize and handle supply-chain workflows.

Have questions?

Learn more about warehouse optimization and its benefits for business

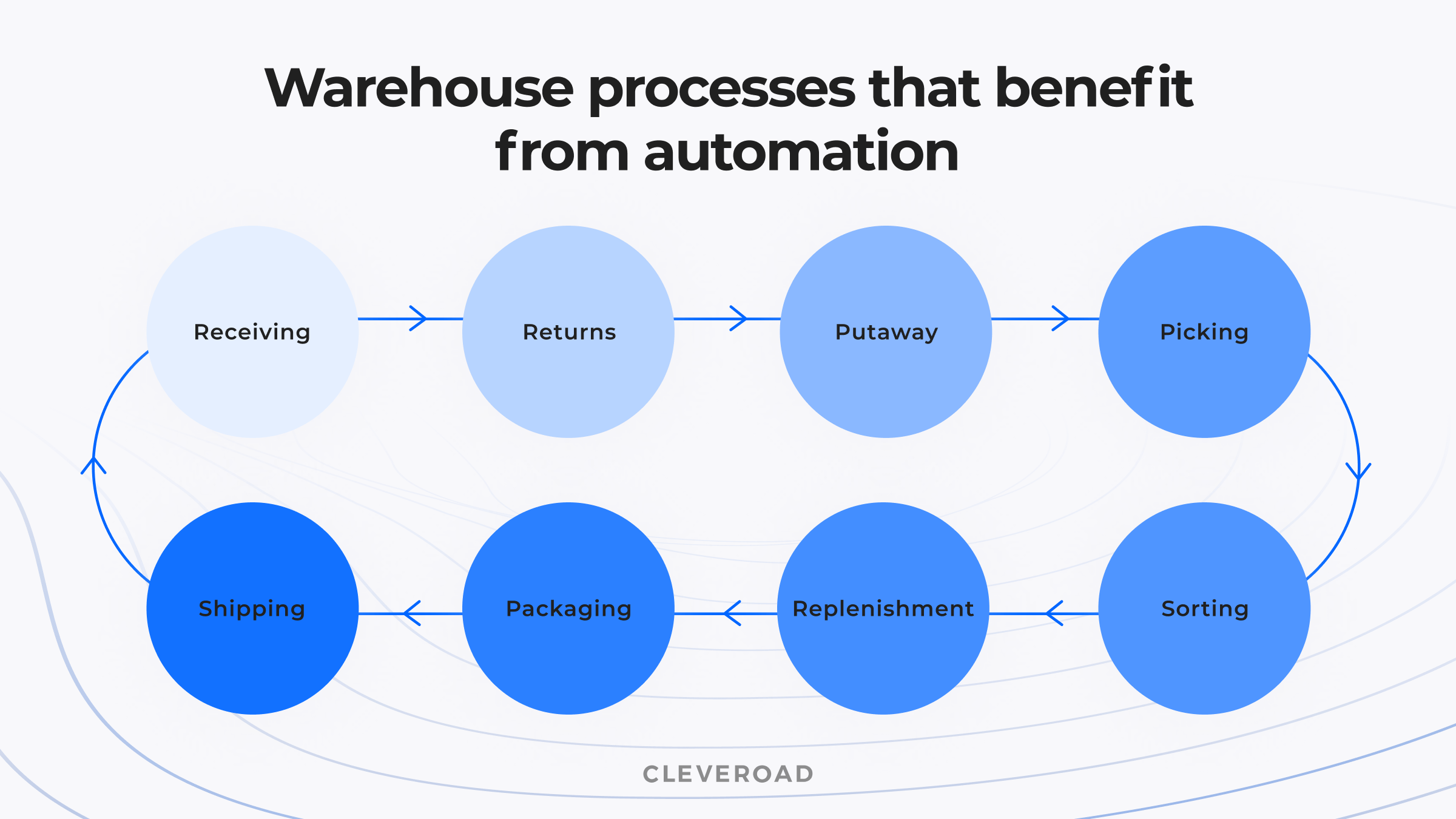

Warehouse Processes That Gain From Automation

The powerful warehouse management software enables you to cover every aspect of the order lifecycle. But how exactly does automation impact different warehouse processes? Let'due south see.

Warehouses processes that tin to be automatic

Receiving

You tin employ smartphones to gather goods receiving-related information. Integrated software will permit managers to collect, handle, and go along information that affects current and farther automatic workflows.

Returns

Return procedures can be automated by autonomous vehicles like lifters or conveyors. They can be applied for sorting, returning stocks to shelves, or placing them in assigned inventory locations.

Putaway

Putaway implies the products modify status from "receiving" to "storage". Automatic putaway procedure can also simplify cross-docking — the practice of rapid unloading freight from trucks and loading it onto an outbound truck that's headed towards freight's final destination bypassing the warehouse.

Picking

Manual packet picking is a costly task. It takes approximately fifty% of the working hours for operators to travel through the warehouse. Mobile robots will contribute to the increased freight delivery speed: from goods locations to complete clients' orders.

Sorting

Operators spend considerable time and efforts to sort and consolidate inventory when it can be automatic. Warehouse automation technology like As/RS systems enhances stocks control and quality monitoring past identifying and managing small stocks separately.

Replenishment

When a stock item reaches the assigned nominal level, the WMS systems automatically create a dispatching request. Automating replenishment procedures result in preventing overstocking and stock loss. Thus, lowering warehouse maintenance costs.

Packaging

Behind the packaging automation lies unique algorithms that define the optimal freight packaging types, analyzing production attributes such as longevity, dimensions, and textile prices. The systems besides consider the impact of those materials on the environment.

Shipping

Warehouse equipment coupled with modernistic technology and mobile apps makes information technology possible for transportation organizations to define available carriers, guess freight costs and put labels on bundles for dispatching.

How to Empathise That Y'all Demand Warehouse Automation

When is the time to automate warehousing? Unfortunately, in that location is no standard respond since it depends on various factors. You'll demand to appraise both external and internal processes, scrutinize your supply chain, hire experienced specialists, and place whether your current technologies are enough to meet your curt-term and long-term objectives.

To make it easier for you, we've prepared vi-check questions you lot should consider earlier introducing warehouse automation:

- Exercise you witness the orders' delays due to limited staff members?

- Do your existing warehouse operations accept a labor-intensive nature?

- Is the number of piece of work orders completed decreasing?

- Are your inventory counts wrong?

- Do you lot still rely on outdated warehouse management software and utilize spreadsheets for inventory management?

- Do clients' satisfaction data show the weak spot in the supply chain?

If you've answered "yes" to any of the higher up questions, so it'south time to recollect of warehouse automation.

Benefits of Automation in Warehouse

Implementing automation to heighten warehouse processes bring significant benefits to logistics companies: from increased efficiency to human mistake reduction. Moreover, modern inventory management systems tin cut labor costs past upwards to threescore% while increasing output chapters. Permit's consider the core advantages of warehousing automation.

Increasing speed

Dissimilar technologies under warehouse automation allow operators to identify the items' location in seconds. Better yet, WMS coupled with advanced engineering enable transportation companies to accelerate multiple tasks such as order fulfillment or inventory accounting. As a result, the employees' productivity and efficiency volition ascent.

Maximizing space

Warehouse systems optimize warehouse space thanks to implementing automatic guided vehicles that are responsible for production retrieval and storage. As/RS systems (automatic storage and retrieval organization) besides apply conveyors decreasing the corporeality of space needed for aisles.

Inventory optimization

By minimizing human factors, warehouse automation contributes to optimized inventory command, allowing for more precise inventory counts and inventory data.

Strengthened safety

Warehouse automation software brings products to the managers. As a result, the amount of employees and equipment across the facility is reduced, increasing common safety.

Warehouse Organization to Reach Optimization

How companies can benefit from warehouse automation

Warehouse automation begins with information technology's optimization which is the primal to effective management of all-size storages. The industry standard is organizing the inventory from the bottom up. This approach leaves more free space and helps to create organic paths for machinery placement which impacts on picking accuracy.

In addition, storages make use of vertical space and adopt layouts to keep the optimal traffic flow. Layout optimization supports the master functions of the warehouse, including:

- Cargo storing

- Incoming (reсeipt, returns of goods) and outgoing processes (picking, shipment)

- Other operations (labeling, applying cost stickers, etc)

Hither are some tips on improving a warehouse layout:

Change aisle widths

Past moving storage shelves together, staff can find lots of free space to place other goods. Just brand sure the aisles are wide enough for staff convenience and safety.

Re-organize inventory

Lots of companies make the mistake of placing like goods together. Instead, the meliorate way to store them is co-ordinate to demand. And so it's always amend to identify fast-moving goods closer to shipping lanes.

Remove unsold goods

If the company's running for more than a few months, managers and staff members already know which items sell fast and which don't. The solution is removing non-needed items and thus saving enough storage space for high-selling products.

Measure the travel time

Sometimes the more than free space at that place is, the more than time pickers need to achieve items. So bank check how long it takes to travel within the warehouse and locate areas to exist improved.

According to the 'Warehouse/Distribution Center Survey', average warehouse infinite utilization has risen to 85% in 2020 compared to 78% 3 years earlier. It seems that it is difficult to operate a warehouse efficiently under such a load. However, to make the most of warehouses, companies need to collect relevant data about the facilities kickoff and then cull the best layout depending on it.

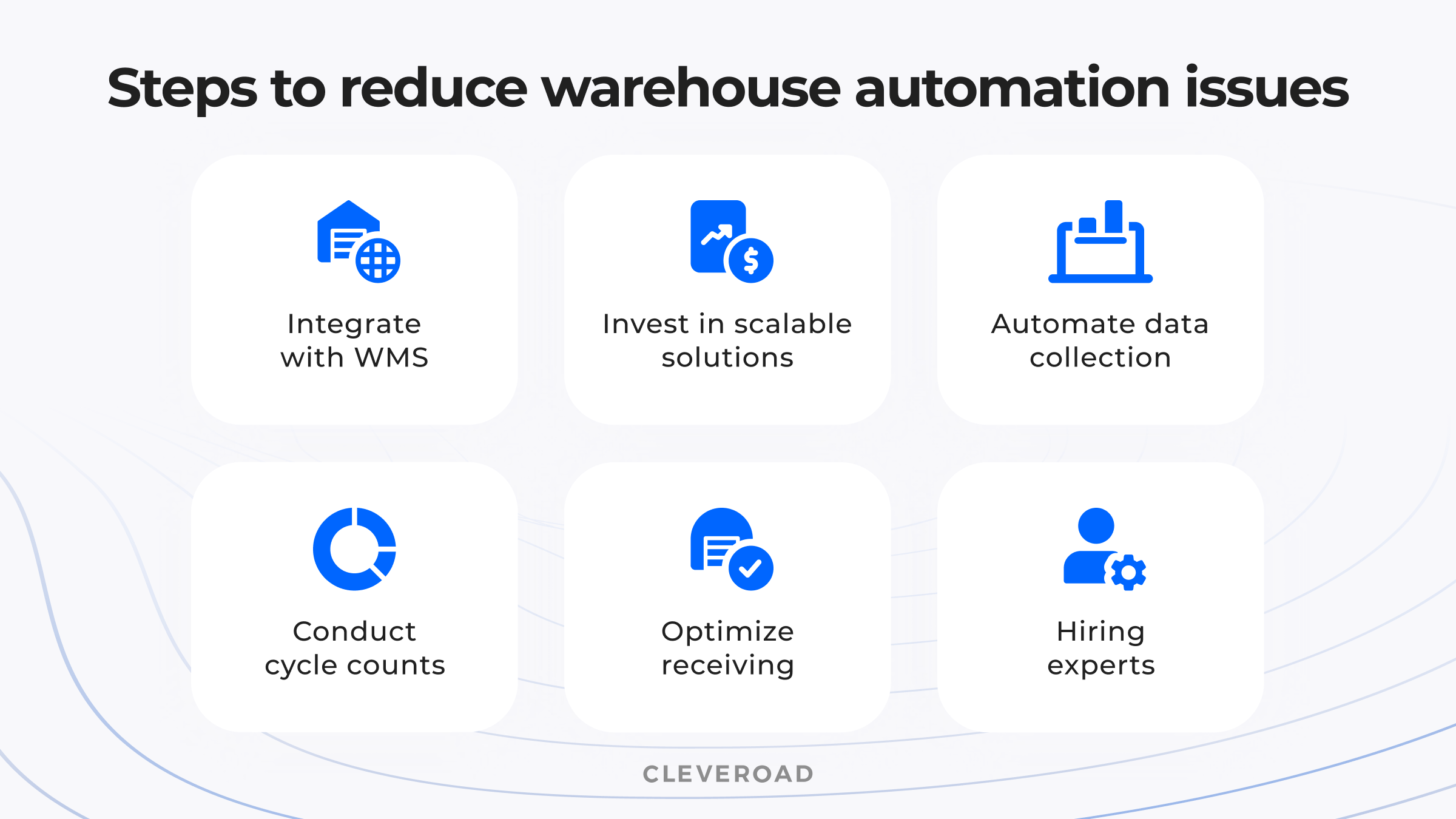

Challenges and Best Practices of Warehouse Automation

Despite many advantages for logistics businesses, automation solutions accept some pitfalls that you should exist set to deal with. For instance, it requires considerable investments to launch and run, and skilled expertise to prepare upwardly and maintain the system, which some organizations need to recruit. Besides, you can face equipment failure resulting in idling and repair costs.

The best style to address those challenges is to implement warehouse automation best practises. Here are some successfully implemented ones.

How to cope with warehouse automation challenges

Integrate with WMS

Your warehouse automation systems take to merge with the warehouse managment system (WMS) platform. Choose a solution that tin automatically handle inventory control, monitor stocks, track and study the staff costs, and incorporate dashboards.

Invest in scalable solutions

Your technology needs to scale every bit the business organization grows. For example, the system has to consider adding new warehouses, workers, and equipment. Even though scalable solutions require high upfront costs, they'll pay off over fourth dimension.

Automate data capturing

Nigh probable, you invest for the long term. So it'due south amend to begin with solutions that automatically get together, transmit, and shop data. For case, cloud-based solutions coupled with mobile barcode scanners will help yous automate warehouse processes with minimum costs and risks. Moreover, such solutions contribute to reducing human mistakes, collecting essential functioning and inventory information, and keeping those data in the central cloud database for further research.

Conduct constant bike counts

Cycle counts are the core WMS characteristic. They monitor stock levels based on stock data recorded. One time y'all set upwards an automatic information capturing system, cycle counts tin can exist automated with mobile barcode scanning or RFID-based sensors. Then you can employ dashboards to examine the stock discrepancies.

Streamline receiving

Whatever data gathering begins with receiving. So, it'southward vital to deploy a system that will exist able to capture a vast corporeality of information in advance for optimized warehouse workflow. Scrutinize the incoming products, then lay down rules in your warehouse management organisation that describe how to command them, where to keep them, and to apply available resource to transport them rationally.

Contracting experts

The warehouse automation procedure is a laborious and challenging task, requiring constant maintenance. So information technology'southward improve to cooperate with an experienced vendor to ensure ongoing warehouse system functionality.

The Automation Foundation: Barcode Labels

At that place are several warehouse automation solutions, simply the easiest and cheapest play tricks is barcode labeling. Past using labels, retailers reduce the number of errors while tracking or shipping appurtenances, or entering their details into the system.

Barcode labels are used for inventory tracking, and this is the basis of the whole automation process. After all, if at that place's no possibility to track items on their way through the facility, in that location can exist no warehouse automation.

Barcode labeling technology brings lots of benefits, some of which are:

- Inventory tracking

Goods are oft lost presently after their arrival due to picking or ordering errors. By monitoring each inventory movement from it's arrival to shipping, staff leaves piddling hazard for the goods to be lost.

- Inflow planning

Automatic data collection leads to better preparation and planning. For case, operators tin can easily check if the shipment inventory arrives at the dock at the same time cargo does.

- Improved picking efficiency

Having all the needed information in-hand, operators ensure timely divergence and delivery of every item. They can too reallocate workers to high priority areas preventing delays due to staff shortages.

- Traffic optimization

Warehouse signs can be used to speed the cargo flowing through the facility. They also work for optimizing the traffic flow and help workers to identify specific areas and shelves for unloading or picking.

- No 'out-of-stock' situations

As software tracks goods on all the stages and these details are synched with WMS, at that place will exist no 'out-of-stock' issues. The system volition automatically re-lodge items when their amount is close to a pre-defined threshold.

Software and Hardware Solution for Automation

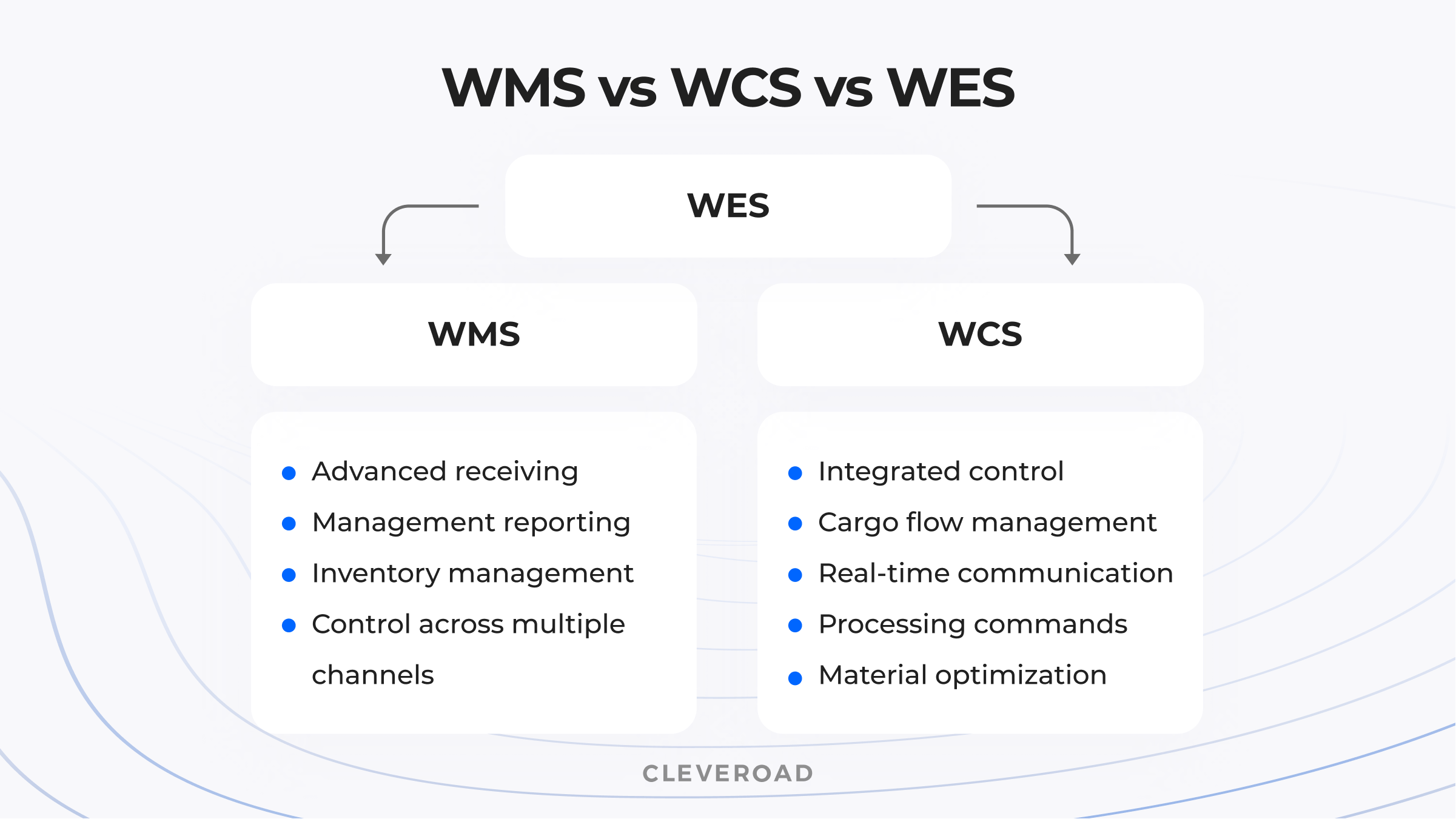

No thing how advanced the technology is, at that place tin exist no automation in warehousing operations without hardware and software to control it. When it comes to software solutions, companies demand to cull one of the three options: WMS (warehouse direction system), WCS (warehouse control organization), or WES (warehouse execution system).

Let's find out what are they, and what's the main divergence.

Warehouse Management System

A WMS is a specialized solution that manages inventory catamenia (to, within and out of a distribution centre), labor tasks and orders. The chief use of the model lies in inventory direction, tracking, and control beyond multiple channels and customers.

Warehouse Control System

A WCS is an integrated command application which manages the flow of goods, cartons, and pallets when they're being moved past automated equipment (conveyors, sorters, ASRS, etc.) The organisation's used for existent-time advice exchange, processing commands, and material optimization.

Warehouse Execution System

WES is an 'all-in-one' solution, combining some WMS and WCS features. The organization is practical for light task management, inventory management, goods picking, and shipping. WES works for pocket-size and mid-sized retailers, managing the fulfillment to both customers and shops.

And so what system to choose? Information technology depends on the way inventory moves through the warehouse. For non or depression-automated facilities, WMS appears to be the best software solution while highly-automated warehouses tin can rely on WCS or WES.

Warehouse software comparison

Got lost?

We'll consult yous on warehouse optimization and help to draw upwardly the all-time software solution.

Finally, let'southward bank check what hardware is required for warehouse automation. The most common devices include:

- Portable data terminals

- Barcode scanners

- Characterization printers

- Rugged tablets

- Fixed mountain computers

When choosing software and hardware, pay attention to their compatibility and performance. Well-fitted solutions are fully compatible and work seamlessly, making the warehouse well-established and set up.

Best Warehouse Automation Examples

According to Hokey Min research, companies that practical warehouse management software observed a 25% proceeds in productivity, 10-20% improvement in space utilization, and 15-30% reduction in safety stock.

Yet, it's always better to take a await at real examples. So hither's our list of acme three companies that automated warehouses.

Amazon

Amazon has i of the largest storage spaces (virtually 150 meg cubic feet), and such volumes practise require an avant-garde management system. Then the company uses inventory management software for checking where every item is shelved and making routes for pickers to collect items in the shortest time.

How Amazon warehouse works

Nike

Nike makes use of warehouse hardware and software to operate it's two-million-foursquare-foot distribution heart. Their Crisplant's LS-4000 handling organisation and it's controller (interfaced to Nike WMS through a warehouse control arrangement) combine precise control of machines with organization-wide visibility of workflows, ensuring faster throughput and higher productivity.

IKEA

And if you're the world's leading home furnishing retailer, an automated inventory management organisation is a must. That'due south why IKEA's managers employ software to make sure everything is in identify and each product is tracked. Their supply chain management organization is powered past automated software. This allows the company to save on warehouse space, collect accurate information, and ensure on-time delivery.

Warehouse Automation Procedure

Now, let'due south discuss what steps you should follow to automate your warehouse operations.

Build an Implementation Board

Create an informational group aware of electric current warehouse operation, its capabilities, and possible risks and comprehends the existing digital gap. It'due south likewise needed to involve third-party specialists who empathise supply chain automation and have relevant manufacture expertise.

Gather Disquisitional Data

Warehouse automation is based on information most your ongoing distribution chain and strategic warehouse processes. To embed automation technology successfully, you demand to establish a information gathering workflow and evaluate the current infrastructure. In fact, information technology'southward better to consul data migration to experienced Information technology vendors.

Appraise Your Inventory Controls

Inventory management is at the heart of every warehouse performance. Earlier implementing a supply concatenation automation solution, defining and improving your standard operating procedures (SOPs) for inventory optimization is vital. SOPs need to exist included for purchasing, dispatching, receiving, clients' enjoyment, and inventory loss.

In addition, disquisitional key functioning indicators (KPIs) should be determined to measure the progress of automatic inventory management processes. Finally, the current inventory accounting method needs to exist assessed to understand how the automation volition impact information technology.

Adopt a Warehouse Management Organisation (WMS)

Warehouse direction system or WMS incorporate software and processes that assist employees in controlling and monitoring inventory, handling warehouse operations, and cut labor costs by reducing man involvement, and enhancing clients' service. Mod WMS interact with smartphones and should be able to back up your current enterprise software.

Decide What Kind of Warehouse Automation You lot Need

Let'southward say you desire to optimize the manual data entry or lower employment costs connected with accounting. Or you're planning to aggrandize the warehouse area or open new distribution points, and you make up one's mind it's time to implement, for instance, goods-to-person solutions (GTP) to automate physical operations and speed upward your overall business processes. Of form, the selected type has to comply with your enterprise goals and market demand.

Warehouse Automation Technologies

There are many technologies that assistance employees manage a variety of logistics-related tasks. We've rounded upwardly the trending ones that you tin can apply to streamline supply chain processes.

- Goods-to-person solutions (GPT)

GPT technologies are designed to help managers assemble and pack goods. All the needed materials are brought by robots. Such solutions encompass automatic storage and retrieval systems or AS/RS systems. They consist of machines that motion upwards and downward storage aisles, placing or retrieving items. These systems aid relieve on inventory storage, every bit a better-staffed warehouse — both vertically and horizontally — results in meliorate storage density.

- Pick-to-light systems

Such solutions assist operators find the right items to carry out the orders. How does information technology work? The worker scans the barcode attached to the shipping cartons. So, the system lights the path to atomic number 82 the worker to the stated storage location. After the managing director picks the needed items and puts them in the container, they press the confirm picking button. Pick-to-calorie-free systems enhance employees' productivity since it allows managers to locate the goods faster.

- Voice picking

Voice picking applied science or voice-directed warehousing (VDW) enables picker-tasker communication. Using wireless headsets, taskers guide the worker to the indicated place and inform them in picking tasks. Every operator carries a headset with microphone, mobile device, and, in some cases, a barcode scanner. The tasker instructs the workers virtually which picking tasks need to be fulfilled and where.

- Sortation systems

Sortation systems involve mobile sort stations composed of smart kiosks, mobile put-to-light systems, and robots. Such solutions permit warehouse assembly to pick and sort the incoming goods for returns, picking, or packing. Once the operator scans the item'southward barcode, the arrangement's alphanumeric display illuminates, lighting up the right shelf or bins to place the item.

- Drones

Drones, set upward with barcode scanners, are used in warehousing to run inventory counts and alert the warehouse associates well-nigh the items that demand to be restocked or relocated. Besides, some logistics companies consider using drones and unmanned aerial vehicles for deliveries.

Even though different technological solutions are created to accelerate warehouse processes, the last choice volition depend on your business goals.

When information technology comes to software, warehouse automation has a case by case basis. For case, ready-made applications ofttimes miss features like press barcode labels, majority options or integration with other systems. And that's the time for custom software development to take the atomic number 82.

So the best mode to start and – what'south more important – successfully finish warehouse automation is to contact an experienced vendor and hash out your plans and ideas with them.

How Cleveroad Can Help You lot

Cleveroad is a software development company from Republic of estonia helping businesses to create any-scale software solutions. With over 10+ years in software development, we have built up expertise in multiple domains, including eastward-commerce, retail, educational activity, healthcare, finance, and Logistics software development.

Our squad create powerful software that helps you lot better warehouse performance, customer experience, and business concern toll-efficiency.

We work with three types of contracts – Time and Material, Fixed Toll, and Dedicated Team. Our evolution approach slightly differs for each of them.

- Fourth dimension and fabric. We give a client an gauge estimation of the scope and start a project without having an exact scope of work in hand. We programme each sprint and agree on all the project details with the customer. According to this approach, we can make changes even in the eye of the software development process.

- Fixed Price. This model implies a fixed scope of work, detailed estimations, articulate requirements, and strict deadlines.

- Dedicated squad. This type of contract is the right solution for big-calibration and circuitous projects like warehouse automation. We agree on cooperation terms and submit software developers to the client's project.

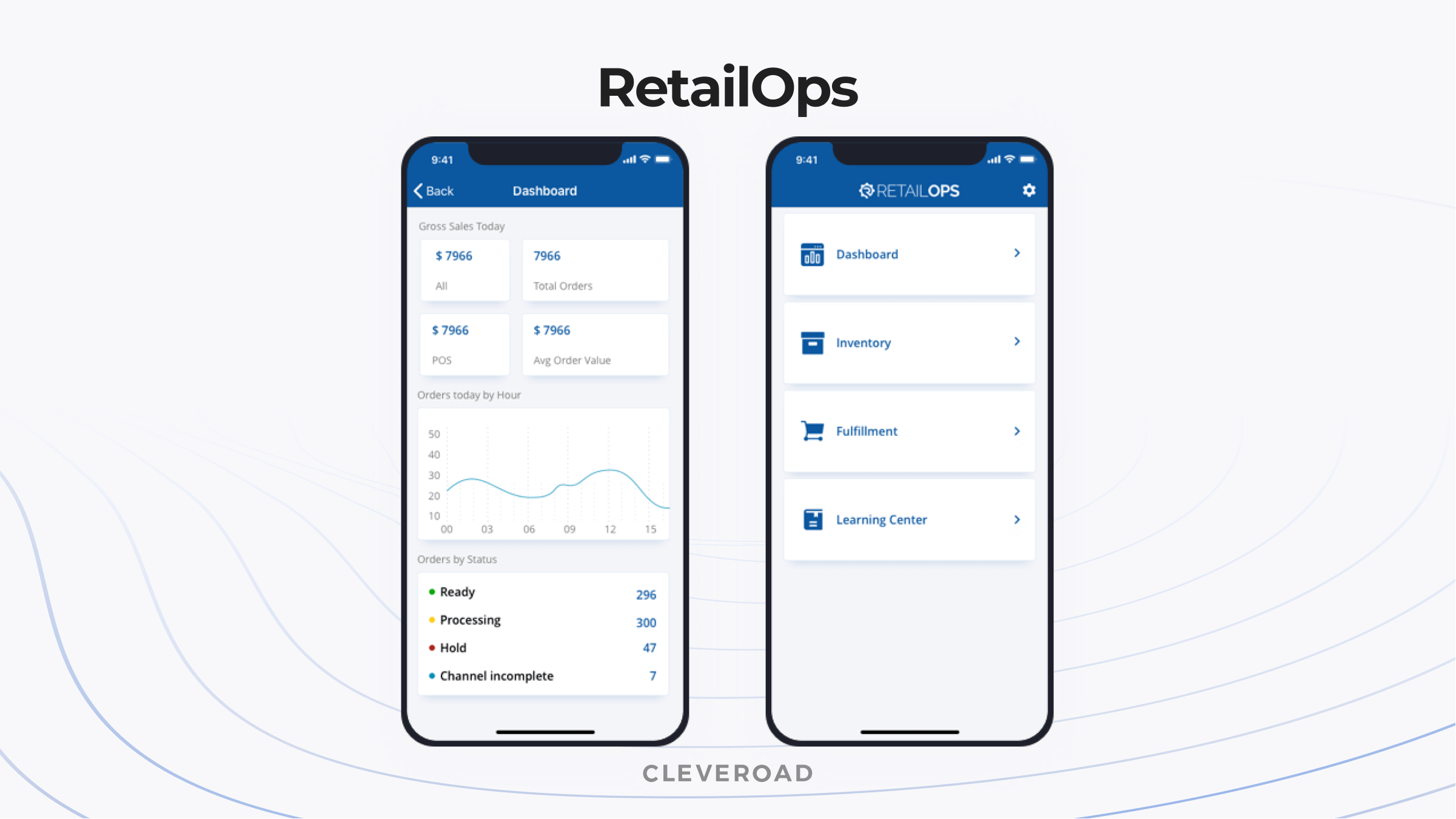

For this time, our team developed and released many software solutions for logistics companies. The latest ones — RetailOps.

RetailOps

Platforms: iOS, desktop

RetailOps is an intuitive and unified SaaS platform for back-role. Offering WMS, IMS, PMS, and other solutions.

It'southward master features include warehouse management, inventory management, tracking, receiving, and many more.

Nosotros've integrated the platform with the Socket Mobile barcode scanner, connected printers available on PCs to portable data terminals. And ensured inventory tracking – from the moment it arrives on a warehouse to the infinitesimal it ships.

RetailOps iOS design

When information technology comes to software, warehouse automation has a case by example ground. For case, ready-made applications oft miss features like printing barcode labels, majority options or integration with other systems. And that's the time for custom software evolution to take the lead.

So the best way to showtime and – what's more important – successfully end warehouse automation is to contact an experienced vendor and discuss your plans and ideas with them.

Optimizing warehouse management?

Get a WMS tailored to your workflow! We'll aid with development and estimate it for complimentary.

Oft Asked Questions

Warehouse automation is all most uncovering repetitive tasks and finding means to automate them. Modern warehouses are full of cases – from manual data entry to picking, storing and shipping of appurtenances done by mitt.

Warehouse automation begins with it's optimization which is the key to effective direction of all-size storages. The industry standard is organizing the inventory from the bottom up. This approach leaves more than free space and helps to create organic paths for mechanism placement which impacts on picking accuracy.

Warehouse automation solutions reduce the expenses and put the workflow optimization on a brand new level. Fourth dimension-efficiency and reduced workload of your employees lead your company to success.

It depends on the style inventory moves through the warehouse. For not or low-automated facilities, Warehouse Management System appears to exist the best software solution while highly-automated warehouses can rely on Warehouse Control Systems or Warehouse Execution Systems.

Charge per unit this article!

4833 ratings, average: iv.79 out of v

Give u.s.a. your impressions about this article

Give us your impressions most this article

0 Response to "Why Dont Hardware Stores Sell 3 Phase Breaker"

Post a Comment